Simple Technology, Difficult to Model

Six less obvious reasons why modelling wind turbines is hard.

Article - 03.06.2021

George Box once said “all models are wrong, but some are useful”. Whilst this was originally said for statistical models, it more than applies to wind turbines. In this short piece, I’m going to touch on 6 less obvious reasons why modelling wind turbines (WTs) is hard, and only getting harder.

Please enjoy my bespoke, handmade, artisan, whiteboard diagrams.

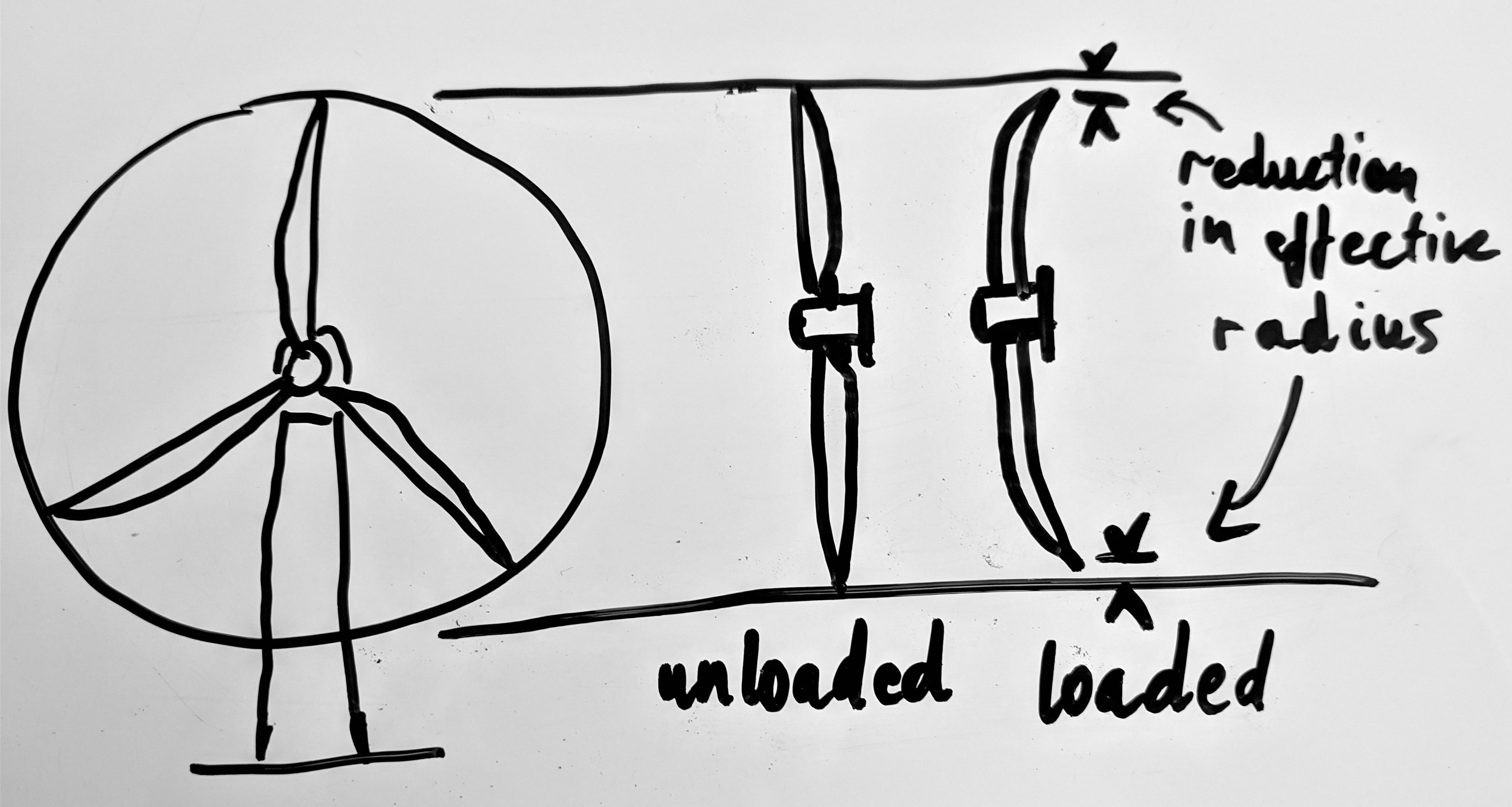

1 – Swept Area is a Dynamic Value

The swept area of a WT is shown below. As blades get longer and more flexible, old theories about deflection being negligible no longer apply. In fact, the deflection is so great that we now need to consider “effective” swept area. This adds complexity into modelling as a smaller area means smaller force from the wind so less deflection so… ↱↵

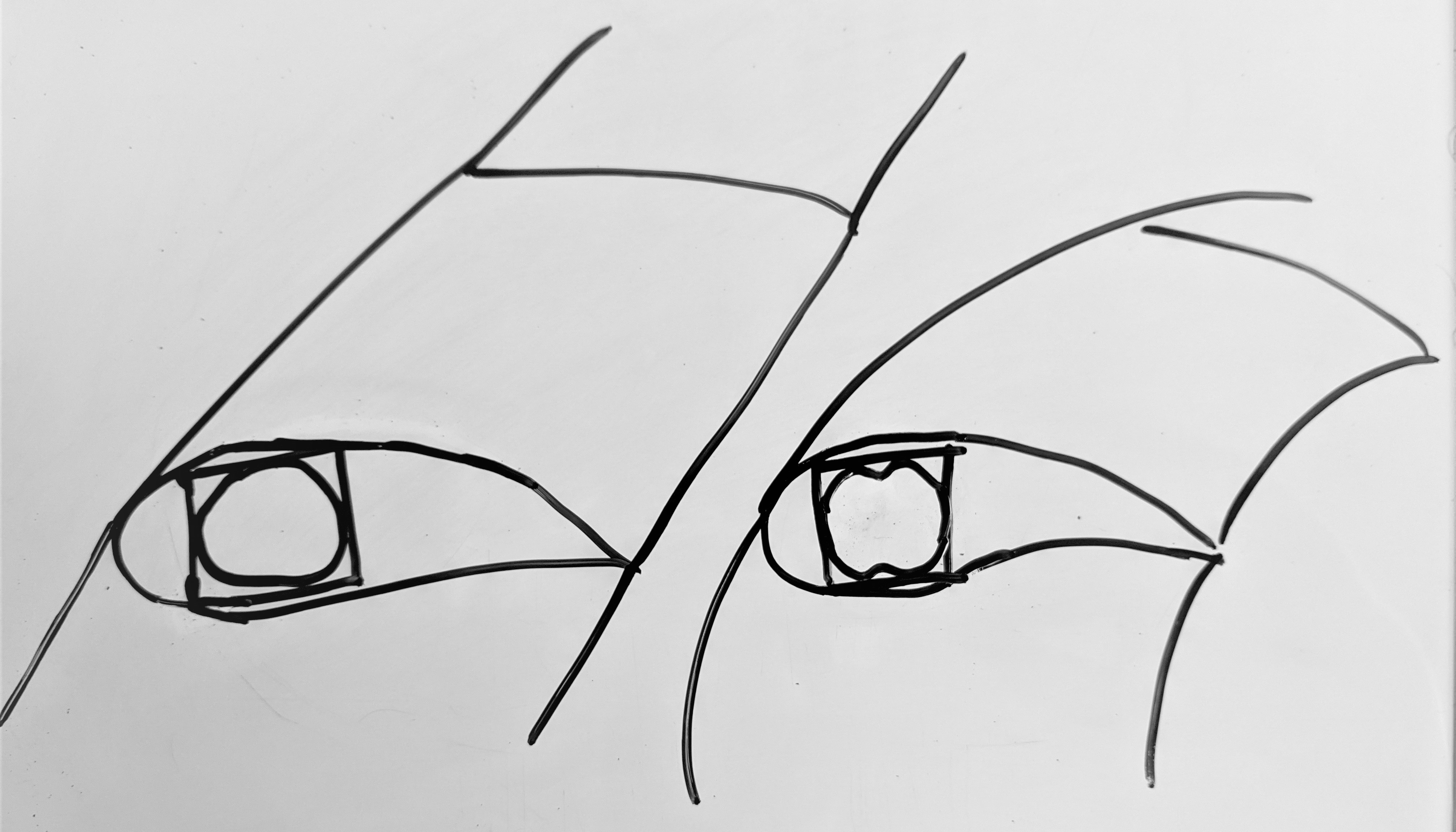

2 – The Brazier Effect

A blade’s stiffness is highly reliant on the materials used and the cross-section. A complication is that as a blade bends, its cross- section becomes deformed. This in turn affects the stiffness of the blade. It used to be that blades were short enough to neglect this changing cross-section, however, that no longer applies with today’s lengths. This gets even more complicated, as circular sections will exhibit the Brazier effect under bending. This is an oval-ing and eventual kinking of the circle, as shown in the poorly drawn diagram below. All of this contributes to blades having non-linear responses to bending forces.

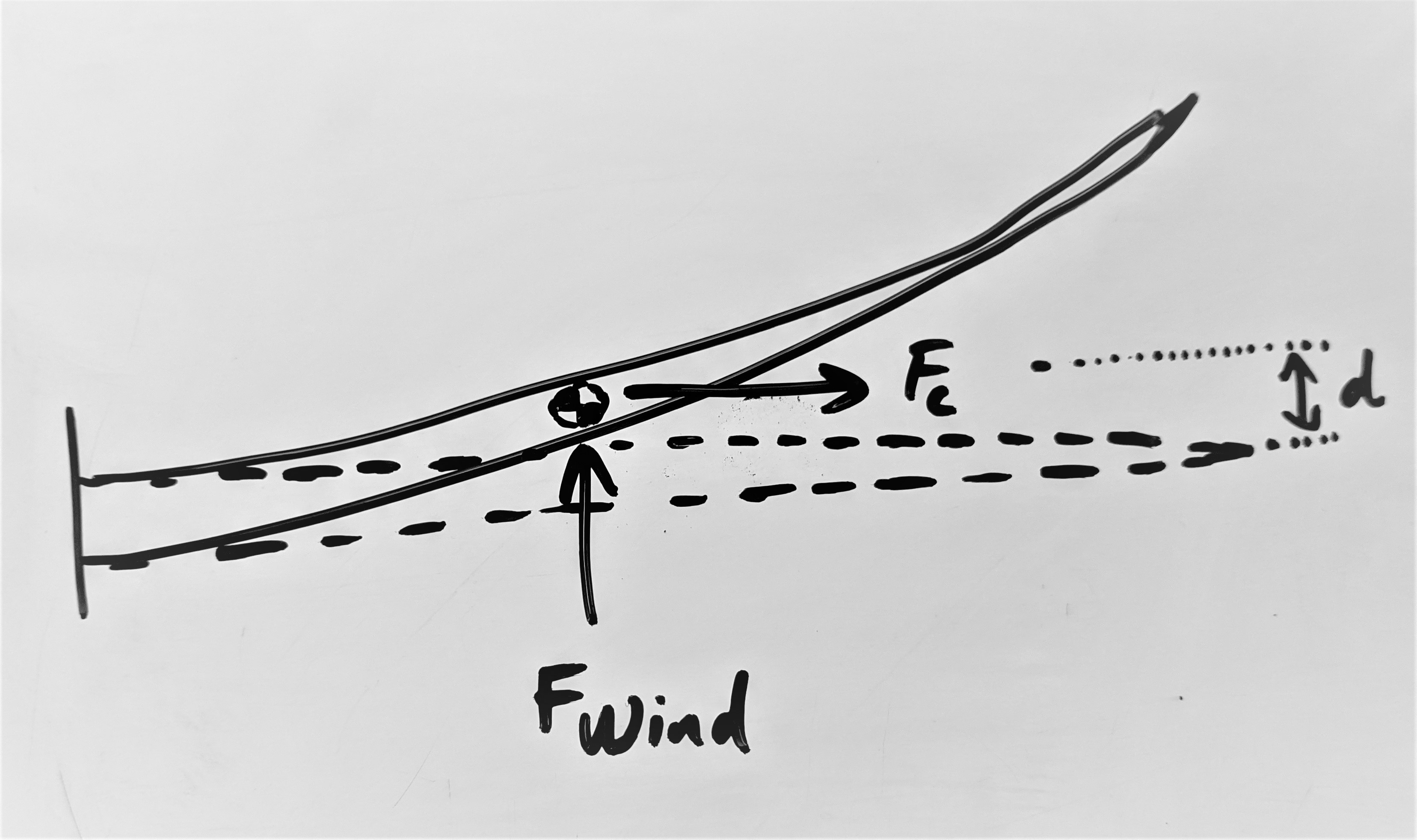

3 – Centrifugal Stiffening

One thing that is somewhat on the blade designer’s side is centrifugal stiffening of the blades. As below, as the blade bends the centrifugal forces will act at a displacement, d, from the centre of mass of the blade. This will create a moment about the root of the blade which will counter the moment created by the force of the wind. As the wind speed increases, both deflection and RPM, hence, centrifugal forces, will increase so increasing centrifugal stiffening. Another force which increases centrifugal stiffening is the Coriolis force, but that’s a topic for another day.

4 – Towers Induce Blade Vibration

As the blades pass by the tower, they will experience a drop in pressure. This unloads the blade and, as the blade is flexible, so starts vibrations. These vibrations will be damped as the blade continues on its path thanks to viscous effects. However, these vibrations will change the performance characteristics of the blade, so that means that the 3 blades will be experiencing substantially different forces at any instant. As such, the rotor experiences an unbalanced force.

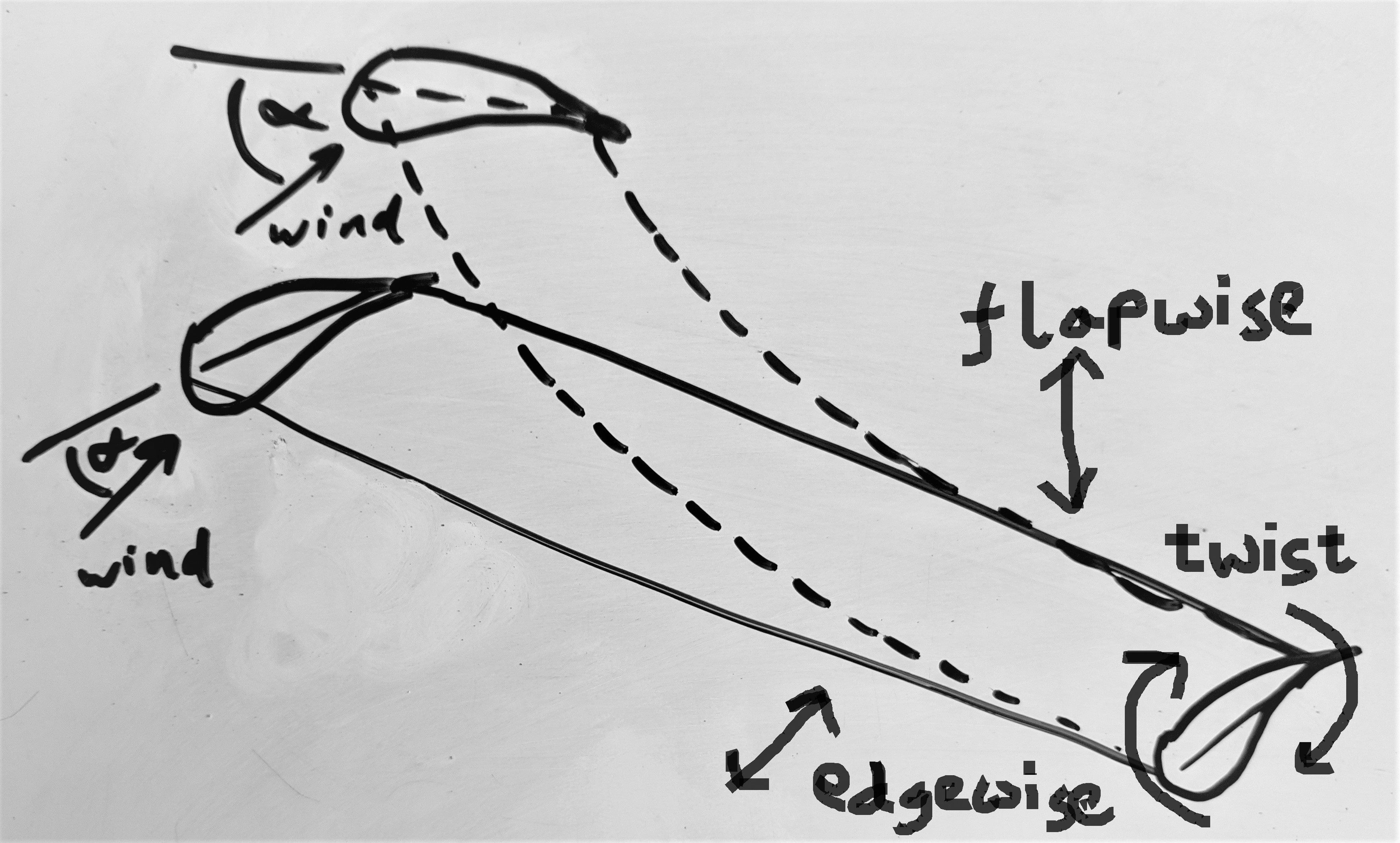

5 – Changing Angle of Attack

Angle of attack is the angle between the incoming wind and the chord line of an aerofoil. Designers/operators consider this angle, and the direction of the resultant force. The problem is that these are elastic components which means that once the blade deforms under this force then the chord line will not be the same. This changes the resultant force so… ↱↵ Note that this isn’t a new consideration, blades are designed with pre-twisting.

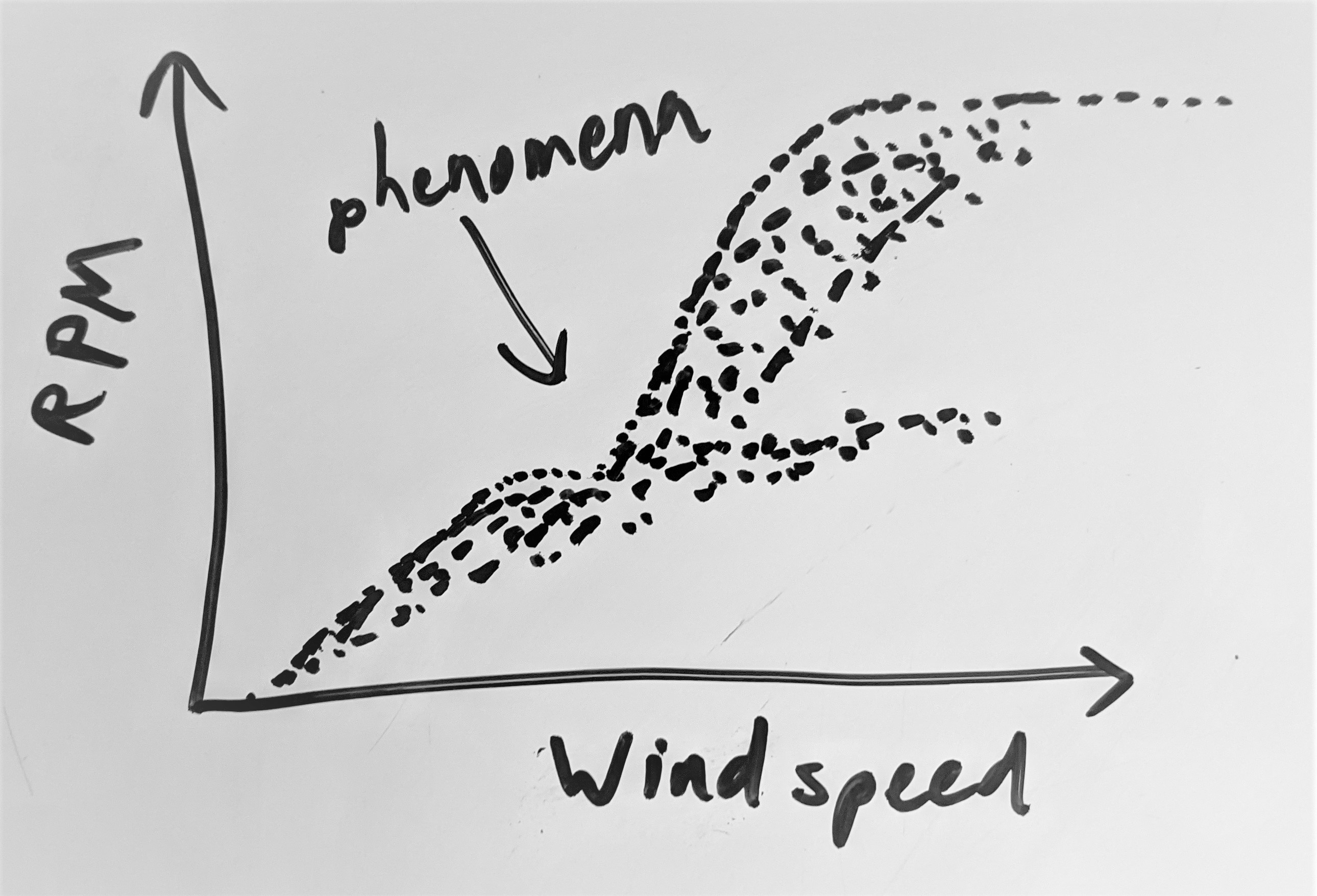

6 – Sommerfeld Effect

This is a phenomenon not exclusive to wind turbines. First, consider that, as per #4, some energy is being wasted in vibrating the blades rather than turning them. The Sommerfeld Effect is a strange point where adding more energy into the system (by increasing windspeed) only makes the blades vibrate more and doesn’t make the rotor spin faster. Adding enough energy into the system will eventually jump past this resonant state but the system can become stuck.

Conclusion

Ultimately, modelling WTs is a tricky business and getting trickier as blades get longer and longer. To put a positive spin on that, this just means our understanding is increasing and our models are getting more useful.

On another positive note, the computational power we have these days makes running these models in higher fidelity and/or shorter timescales more feasible. Additionally, we also have new computational strategies such as Machine Learning and parallel computing, which will improve performance. The former is the basis of my PhD research.

Thanks for reading. If you want to read more about the above, and you have a day to spare, I suggest reading this paper: “Horizontal axis wind turbine research: A review of commercial CFD, FE codes and experimental practices”, O’Brien et al, 2017.

Rory Morrison

This article was originally posted on LinkedIn